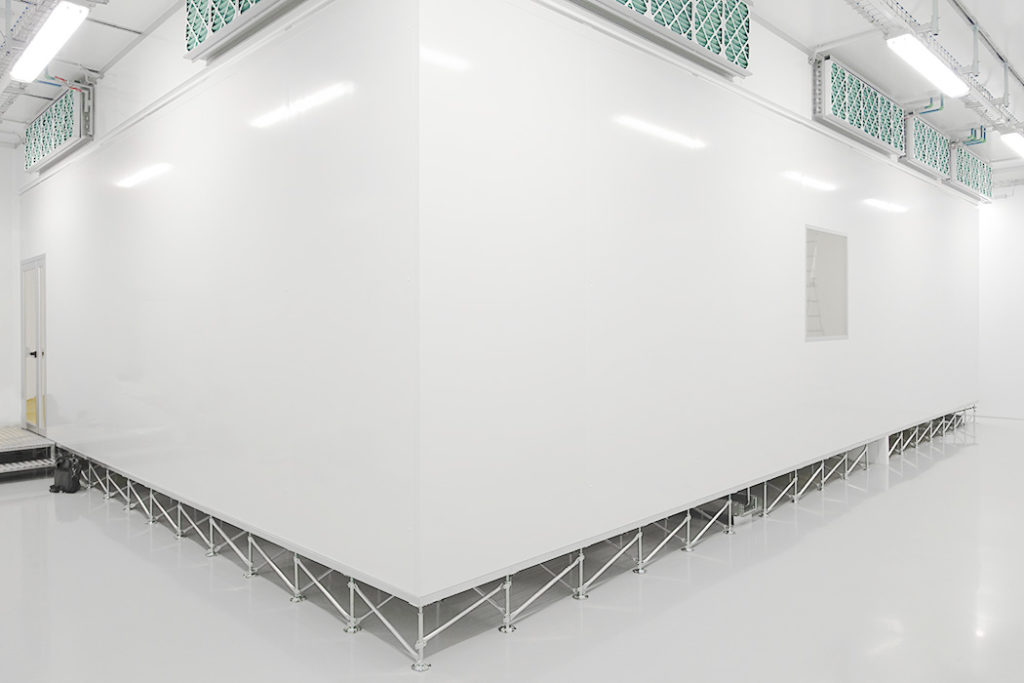

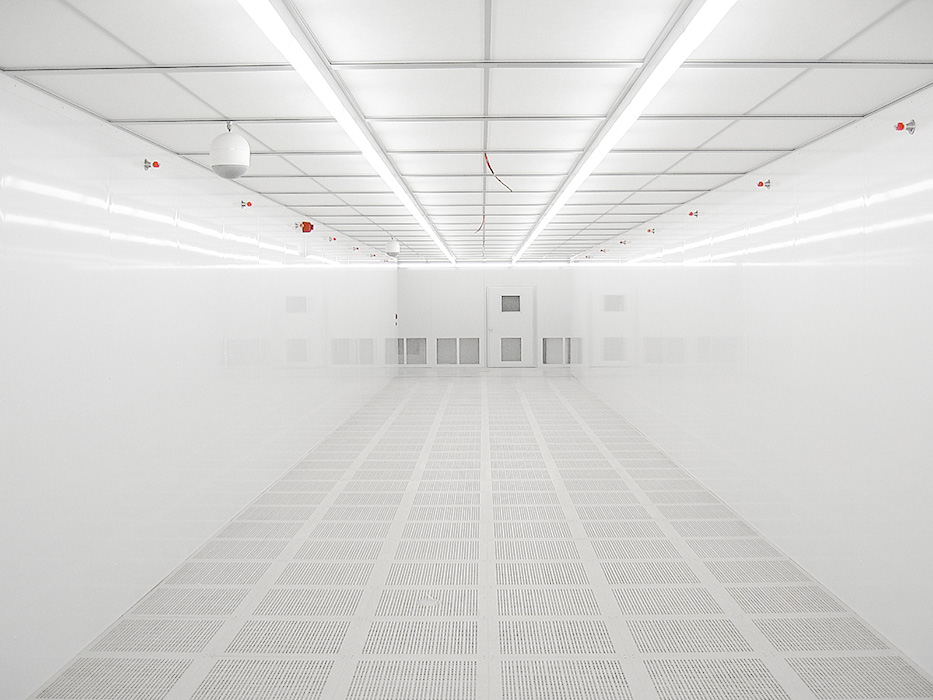

Clean Room

From the semiconductor, electronics and automotive industries to food, pharmaceutical and biomedical sectors, Galvani always finds the perfect solution to satisfy various cleanliness needs in contamination-free environments.

The only company in Italy to directly manufacture the components needed, Galvani brings its own expertise and know-how, and takes great care in ensuring safety, comfort and highly customisable solutions.

The result? Efficient, bespoke and ready-to-use Clean Rooms in which meticulous attention has been paid to every detail.