Manufacturing a Clean Room

The attributes of our in-house manufacturing process make Galvani a unique Clean Rooms manufacturer in many ways: we provide highly customised and non-standard solutions; time-frames are totally flexible; we use Italian and European components; and we always deliver on time

Testo finto finto finto testo testo

Testo finto finto finto testo testo

Manufacturing a Clean Room

The attributes of our in-house manufacturing process make Galvani Clean Rooms unique in many ways: we provide highly customised and non-standard solutions; time-frames are totally flexible; we use Italian and European components; and we always deliver on time

Analysis

Analysis

The Clean Room journey

At Galvani, we believe in paying close attention to every single detail. This is why we scrupulously follow every step involved in creating the Clean Room, from analysis to validation, as well as subsequent periodic maintenance.Get in touch for more information

Clean Room Manufacturer

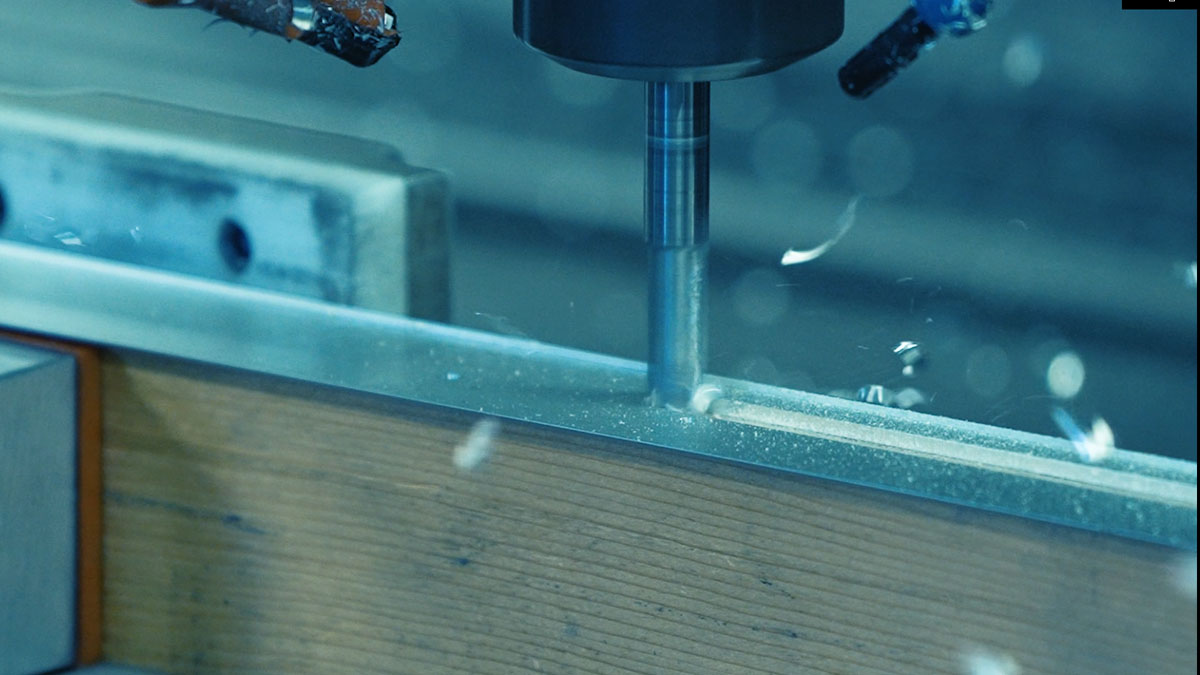

Being a direct manufacturer means guaranteeing reliable, tested solutions that adhere to the highest safety standards. In addition, thanks to our experience, know-how and expertise, we are able to create components that are unique in terms of performance, attention to detail and customisation.

Most of the parts used for our Clean Rooms are manufactured in our workshops, and we use trusted, proven and carefully selected partners for the rest.

Italian and European components

Each component of our Clean Rooms is either manufactured in-house in Italy, or provided by carefully selected partners in Europe.

The materials used must pass a thorough evaluation, which considers:

- Cleanliness class

- Recovery time

- Reliability over time

- Accessibility and maintenance

- Flexibility, expandability and ease of implementation of areas concerned

- Effects of abrasion and impact

- Cleaning and sanitising methods/frequency

- Corrosion caused by chemicals.

Bespoke and non-standard solutions

We create solutions tailored to the needs of the client and adapted to the processes involved, paying close attention to every single detail. These fully bespoke solutions are ideal for the various operations that take place inside and around the Clean Room. Our in-house production process enables us to handle non-standard solutions with ease, ensuring the same performance and quality of standard products.

Flexibility during production and set times

Changes during the project-development stage or critical issues that may arise during installation, are not a problem: our in-house workshops allow us to deal with any kind of unforeseen event that may occur throughout the various stages quickly and with expert skill. Thanks to this flexibility, we are able to provide set times and comply with delivery agreements.

Certified manufacturing processes

By overseeing the manufacturing stage directly, we can be sure that our solutions satisfy the relevant European quality standards and current regulations in each country. We offer clients secure ISO 9001:2015-certified products, and compliance with ISO 14001:2015-certified international guidelines regarding cleanliness, safety and environmental protection

Unique

for 6 reasons

Offering an all-inclusive, turnkey service, we are experts in planning, designing, directly manufacturing, validating and installing Clean Rooms. Choosing Galvani means choosing a partner who understands your needs and can provide you with effective, customised, certified and ready-to-use solutions.

Watch the video

Decades of experience in contamination-free environments

Components manufactured directly

Solutions tailored to the customer

Delivered on time

Continued investment in innovation, research and development

Quotes issued quickly

Decades of experience in contamination-free environments

Components manufactured directly

Delivered on time

Solutions tailored to the customer

Continued investment in innovation, research and development

Quotes issued quickly

Different solutions

for different sectors

Knowledge is limited if you do not branch out. At Galvani, we bring our know-how and expertise to different fields, allowing us to find the best solution for any need. Discover the solutions we have come up with for each different sector, or ask us for one tailored to your business.