Automotive Clean Rooms

The automotive sector deals with every aspect of the motor vehicle market, from design to manufacturing and distribution. By using Clean Rooms, companies in this sector can safely manufacture components for complex systems—which require certain contamination-control conditions—to very high standards of quality.

A Clean Room provides an aseptic environment in which there are very low levels of suspended particles, thus protecting each operation from intrusive foreign bodies.

Galvani has in-depth knowledge and extensive experience in creating Clean Rooms for the automotive sector, guaranteeing quality and safety for all of our clients.

Testo finto finto finto testo testo

Testo finto finto finto testo testo

Clean Rooms for Automotive Sector

The automotive sector deals with every aspect of the motor vehicle market, from design to manufacturing and distribution. By using Clean Rooms, companies in this sector can safely manufacture components for complex systems—which require certain contamination-control conditions—to very high standards of quality.

A Clean Room provides an aseptic environment in which there are very low levels of suspended particles, thus protecting each operation from intrusive foreign bodies.

Galvani has in-depth knowledge and extensive experience in creating Clean Rooms for the automotive sector, guaranteeing quality and safety for all of our clients.

Turnkey Clean Rooms for Automotive sector

The automotive sector deals with every aspect of the motor vehicle market, from design to manufacturing and distribution. By using Clean Rooms, companies in this sector can safely manufacture components for complex systems—which require certain contamination-control conditions—to very high standards of quality.A Clean Room provides an aseptic environment in which there are very low levels of suspended particles, thus protecting each operation from intrusive foreign bodies.

Galvani has in-depth knowledge and extensive experience in creating Clean Rooms for the automotive sector, guaranteeing quality and safety for all of our clients.

Discover Galvani Clean Rooms

Characteristics of Clean Rooms for the automotive sector

The primary feature that any Clean Room for the automotive sector must have is an effective system to control the number of suspended particles present, which value-wise, depending on the cleanliness class, vary both in quantity and size. Secondly, certain parameters, such as pressure, temperature and humidity must be monitored and maintained. This will help to ensure that the environment is suitable for automotive-specific processes. If these measures are adopted, elements such as injectors, painting tools, composite fibres and electronic components will benefit from a very clean environment, resulting in a very efficient, high-quality production line.

Technical requirements and relevant standards

The technical standards of a Clean Room, including those made for the automotive sector, must correspond to those required by the various cleanliness classes, ranging from ISO1—the highest standard of cleanliness—to ISO9.

Each cleanliness class has specific parameters for different aspects, including the number of particles per m³ of air, temperature, pressure and humidity.

The ISO 14644 standard sets out and regulates all the guidelines and characteristics concerning Clean Rooms and must be adhered to throughout production.

Uses of Clean Rooms and Dry Rooms in the Automotive sector

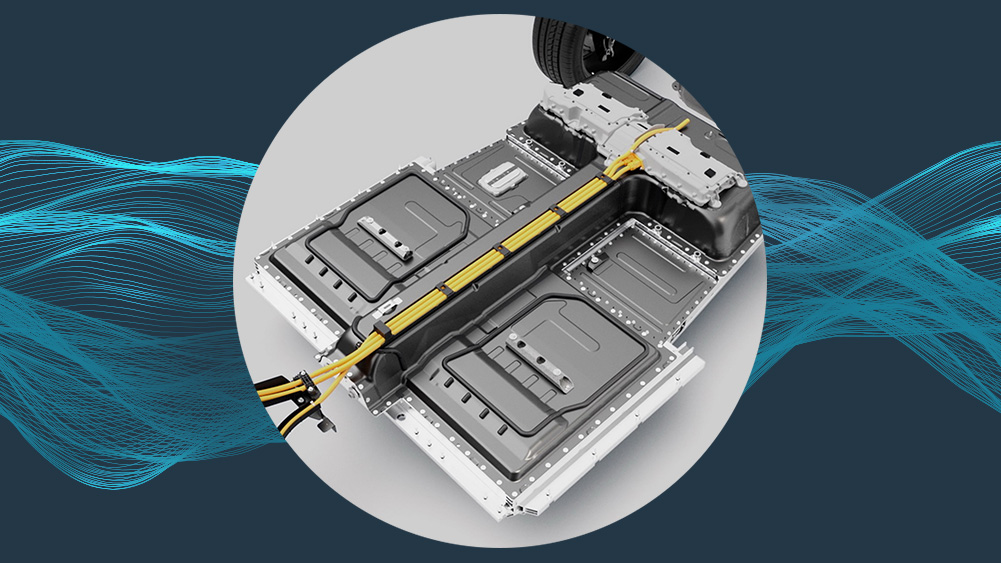

Clean Rooms are used for several aspects of the automotive sector, including the processing of internal components for complex systems, such as injectors and powertrains, painting vehicles, and the manufacturing of electronic components, to name just a few of the main ones.

Dry Rooms are also used for the manufacturing of batteries for electric cars, as these provide protection from excessive humidity.

Additional

Services

Training

The training service is designed to complement our Turnkey Clean Room package: our consultants provide you with all the information you need to use the Clean Room, including how to check parameters and settings. This will help ensure that the controlled-contamination environment continues to perform as well as possible over time, like on the day it was delivered

Scheduled Maintenance and Remote Assistance

Maintenance work, preferably Scheduled, ensures that your solution functions properly for many years and performs as well as possible.

Our specialist operators use sophisticated tools to check the operating condition, replace worn parts and check air-conditioning and heating systems.

This regular work saves a great deal of time and money as our employees take care of everything (there is no need to hire an in-house maintenance technician), and prevents damage and production stops. Regular Maintenance work keeps the Clean Room active and highly efficient at all times.

In addition, all our systems are equipped for the Remote-Assistance service: the technology involved here enables our technicians to view, modify and log—even remotely—the parameters of the Clean Room directly from our offices. A practical, quick and functional service.

Comfort Rate

The well-being of operators is an aspect that must be taken into account. Galvani has created the Comfort Rate system: this tool enables us to assess the level of comfort experienced by those working inside hyper-ventilated environments.

The Comfort Rate ranges from 1 to 6 and the parameters taken into account include the temperature of the air supplied, the ambient temperature desired and the coverage factor.

Solutions

Galvani has the perfect solution for every cleanliness need. When it comes to the mechanics/engineering sector, choosing a Clean Room ensures excellent protection from contaminants, which is essential for many sector-specific processes.

Clean Rooms

A Clean Room is a closed, controlled-contamination environment: air cleanliness, temperature, humidity and pressure levels are kept under constant control, so that processes and operations that require a clean and well-monitored environment can be carried out inside.

Discover our Clean RoomsDry Room

The main difference between Clean Rooms and Dry Rooms lies in the relative-humidity level, which in a Dry Room never exceeds 5%, while in a Clean Room ranges from 40 to 60%.

Dry Rooms are the perfect solution for lithium-battery manufacturing, as processing that involves lithium electrodes must take place in extremely dry environments to prevent deterioration.

Discover our Dry Rooms