Electronics Clean Rooms

In the electronics sector, electronic components and products, whether used domestically or in various other industrial and commercial settings, are manufactured.

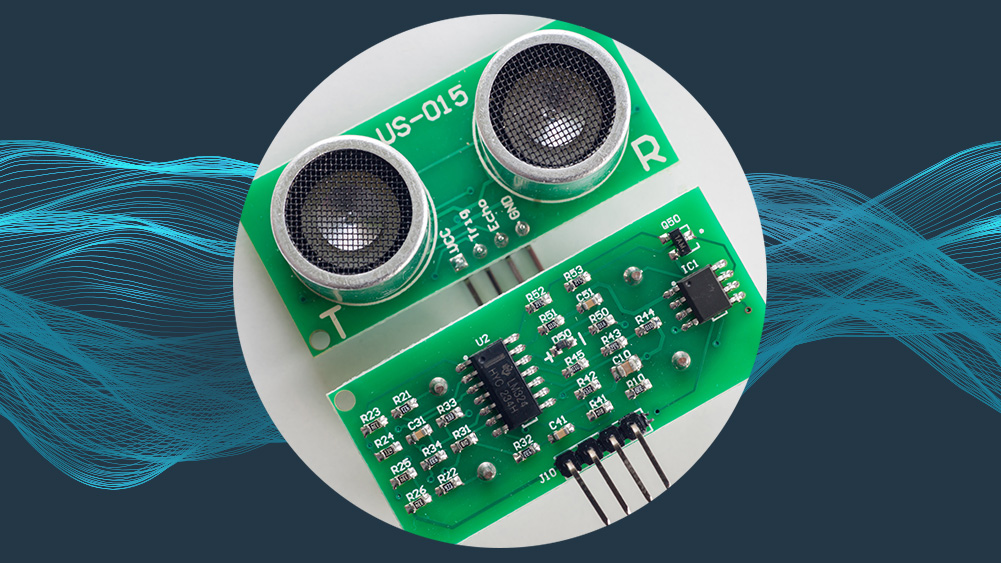

Clean Rooms are needed in this sector because very small parts, which would be adversely affected by excessive levels of suspended particles, are handled.

At Galvani, we have extensive experience, know-how and expertise in creating Clean Rooms for electronics, having manufactured contamination-free environments for renowned Italian and international companies.

Testo finto finto finto testo testo

Testo finto finto finto testo testo

Clean Rooms for Electronics

In the electronics sector, electronic components and products, whether used domestically or in various other industrial and commercial settings, are manufactured.

Clean Rooms are needed in this sector because very small parts, which would be adversely affected by excessive levels of suspended particles, are handled.

At Galvani, we have extensive experience, know-how and expertise in creating Clean Rooms for electronics, having manufactured contamination-free environments for renowned Italian and international companies.

Turnkey Clean Rooms for Electronics sector

The Turnkey Clean Room is an all-inclusive service beginning with an initial analysis followed by the planning, design, manufacturing and validation stages, after which the end product is delivered and ready to useAt each stage, every single detail is closely monitored and scrutinised by our experts in order to provide an efficient, high-quality product that is in step with the latest innovative technologies and complies with the relevant standards.

Discover Galvani Clean Rooms

Characteristics of Clean Rooms for the Electronics sector

As with semiconductors, operations that involve the creation of electronic components require extremely clean air. This is because contamination would negatively affect the quality and performance of the end product. As such, Clean Rooms for this sector therefore require:

- high manufacturing standards

- very advanced technology

- very close attention to detail

Technical requirements and relevant standards

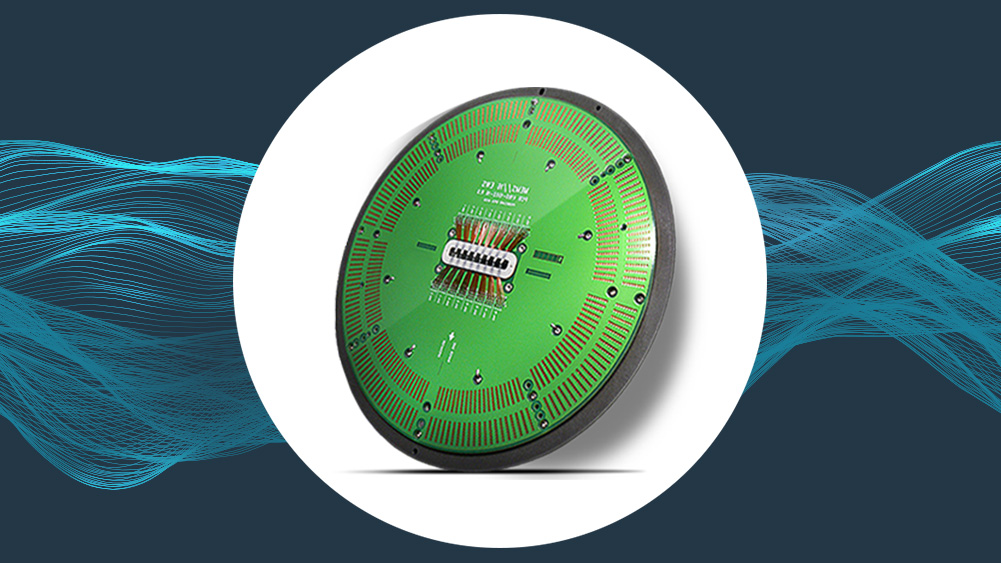

The technical requirements for Clean Rooms for electronics vary depending on the operations carried out and adhere to Clean Room cleanliness classes ranging from ISO 1 (highest cleanliness level) to ISO 9. The main parameters taken into account are: the number of particles per m³, temperature, pressure and humidity.

The ISO 14644 standard regulates the Clean Room sector: it sets out all the relevant guidelines, from analysis to manufacturing and validation. Other regulations, such as the Federal Standard in the USA, are also relevant.

Choosing Galvani means choosing expert technicians who understand the regulations thoroughly and adhere to them throughout.

Uses of di Clean Rooms for the Electronics sector

Additional

Services

Training

To ensure the Clean Room is used properly, we also offer a post-sale training service, which provides instructions and best practices for the client to follow for their contamination-free environments.

Our consultants are always on hand to offer this complementary service, which provides what you need for proper independent use and what you need to know to report anomalies that require targeted action.

Maintenance and Remote Assistance

Scheduled Maintenance is the secret to ensuring that your Clean Room remains in excellent working order. This allows our experts to carry out regular checks, testing parameters and level of wear and tear and promptly replacing parts where necessary.

We also offer a complementary Remote-Assistance service that, with the aid of a basic telephone or internet connection, enables our technicians to view, modify and log the Clean Room’s parameters directly from our offices. The speed at which we can assist the client and efficiency are immediate advantages of this service.

The main advantages of entrusting Maintenance to Galvani include major savings in terms of time and money, as damage and subsequent production stops are prevented, and the convenience of dealing with one partner who knows your Clean Room in and out and can take action promptly.

Comfort Rate

One aspect that sets Galvani apart from other players in the market is the Comfort Rate: this tool is used to assess the level of comfort experienced by operators in the controlled-contamination environment. It is mainly related to the quality of the air distribution and ventilation systems.

Parameters including the temperature of the air supplied, the desired room temperature and the coverage factor are taken into consideration to determine the comfort level, which ranges from 1 to 6.

This focus translates into care and consideration for human resources and improved productivity.

Solutions

A Clean Room is the ideal solution for all operations in the electronics sector: given its characteristics, safety and contamination control—essential for products and processes in this field—are guaranteed.

Galvani Clean Rooms

A Clean Room is a closed, controlled-contamination environment: air cleanliness, temperature, humidity and pressure levels are kept under constant control, so that processes and operations that require a clean and well-monitored environment can be carried out inside.

Discover our Clean Rooms