Clean Rooms for Mechanics

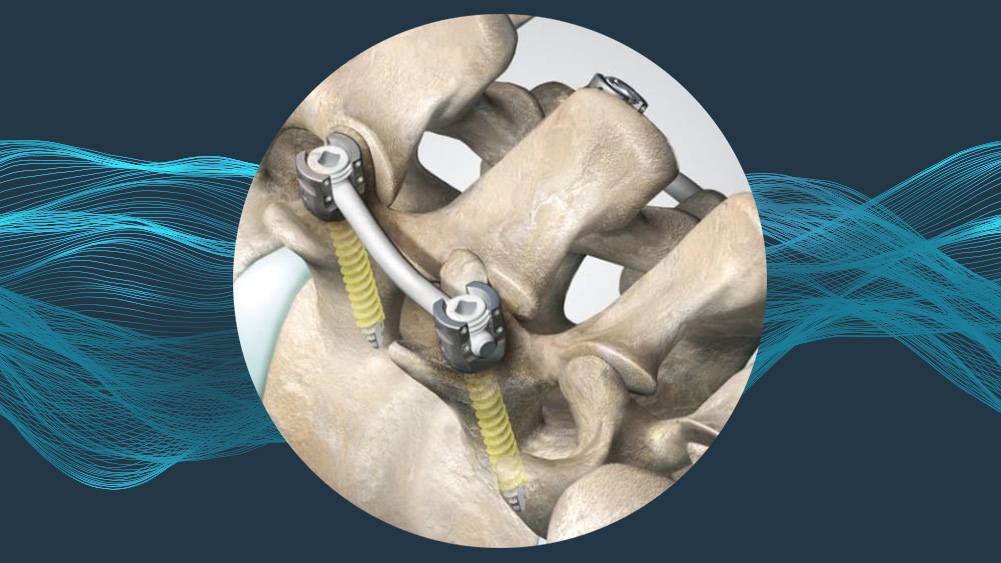

Activities in the Mechanics/Engineering sector include both the processing of metal components and products and the machinery needed to make the products themselves. A very important sub-sector of this industry is the so-called ‘precision mechanics‘ sector, in which extremely small products, such as components that go into making injectors, are manufactured to very low tolerances.

This sector needs Clean Rooms to protect all components that go into making complex machines, whose parts must be integrated without intrusive agents that would negatively affect their performance, from contamination.

To create your Clean Room for mechanical processing, choosing Galvani means opting for an experienced, leading partner who will deliver a Turnkey solution.

Testo finto finto finto testo testo

Testo finto finto finto testo testo

Clean Rooms for Mechanics

Activities in the Mechanics/Engineering sector include both the processing of metal components and products and the machinery needed to make the products themselves. A very important sub-sector of this industry is the so-called ‘precision mechanics‘ sector, in which extremely small products, such as components that go into making injectors, are manufactured to very low tolerances.

This sector needs Clean Rooms to protect all components that go into making complex machines, whose parts must be integrated without intrusive agents that would negatively affect their performance, from contamination.

To create your Clean Room for mechanical processing, choosing Galvani means opting for an experienced, leading partner who will deliver a Turnkey solution.

Turnkey Clean Rooms for Mechanics sector

The Turnkey Clean Room is a service that, from planning and design to validation, results in a controlled-contamination environment that is ready to use. Galvani provides an all-inclusive service that allows the client to put the Clean Room to use immediately upon delivery, without further action or third-party intervention required.Discover Galvani Clean Rooms

Characteristics of Clean Rooms for the mechanics sector

Clean Rooms designed for the mechanics/engineering sector meet the highest standards in terms of suspended-particle control, pressure, temperature and humidity, which are constantly monitored. This ensures a safe environment for manufacturing and assembling components, without the risk of intrusive contaminants getting in, resulting in high-quality products.

Technical requirements and relevant standards

Alongside all guidelines for manufacturing and validation, the ISO 14644 international standard, which classifies Clean Rooms in terms of cleanliness, from ISO 1 to ISO 9, is the benchmark standard for Clean Rooms.

This standard and the process analysis enable us to determine the technical specifications we need to adhere to for each individual Clean Room, which include temperature, pressure and humidity.

Uses of Clean Rooms

for Mechanics

The installation of Clean Rooms for operations involved in manufacturing superconducting cavities, precision machine tools and certain parts for midstream valves is in growing demand from companies.

Superconducting cavities, in particular, are used for physics experiments, so, clearly, preventing contamination from foreign particles is fundamental.

Being able to manufacture, assemble, inspect and test components in these modern, contamination-free environments ensures that the product we provide meets the highest safety and quality standards.

Additional

Services

Training

The training service is designed to complement our Turnkey Clean Room package: our consultants provide you with all the information you need to use the Clean Room, including how to check parameters and settings. This will help ensure that the controlled-contamination environment continues to perform as well as possible over time, like on the day it was delivered

Scheduled Maintenance and Remote Assistance

Maintenance work, preferably Scheduled, ensures that your solution functions properly for many years and performs as well as possible.

Our specialist operators use sophisticated tools to check the operating condition, replace worn parts and check air-conditioning and heating systems.

This regular work saves a great deal of time and money as our employees take care of everything (there is no need to hire an in-house maintenance technician), and prevents damage and production stops. Regular Maintenance work keeps the Clean Room active and highly efficient at all times.

In addition, all our systems are equipped for the Remote-Assistance service: the technology involved here enables our technicians to view, modify and log—even remotely—the parameters of the Clean Room directly from our offices. A practical, quick and functional service.

Comfort Rate

The well-being of operators is an aspect that must be taken into account. Galvani has created the Comfort Rate system: this tool enables us to assess the level of comfort experienced by those working inside hyper-ventilated environments.

The Comfort Rate ranges from 1 to 6 and the parameters taken into account include the temperature of the air supplied, the ambient temperature desired and the coverage factor.

Solutions

Galvani has the perfect solution for every cleanliness need. When it comes to the mechanics/engineering sector, choosing a Clean Room ensures excellent protection from contaminants, which is essential for many sector-specific processes.

Galvani Clean Rooms

A Clean Room is a closed, controlled-contamination environment: air cleanliness, temperature, humidity and pressure levels are kept under constant control, so that processes and operations that require a clean and well-monitored environment can be carried out inside.

Discover our Clean Rooms